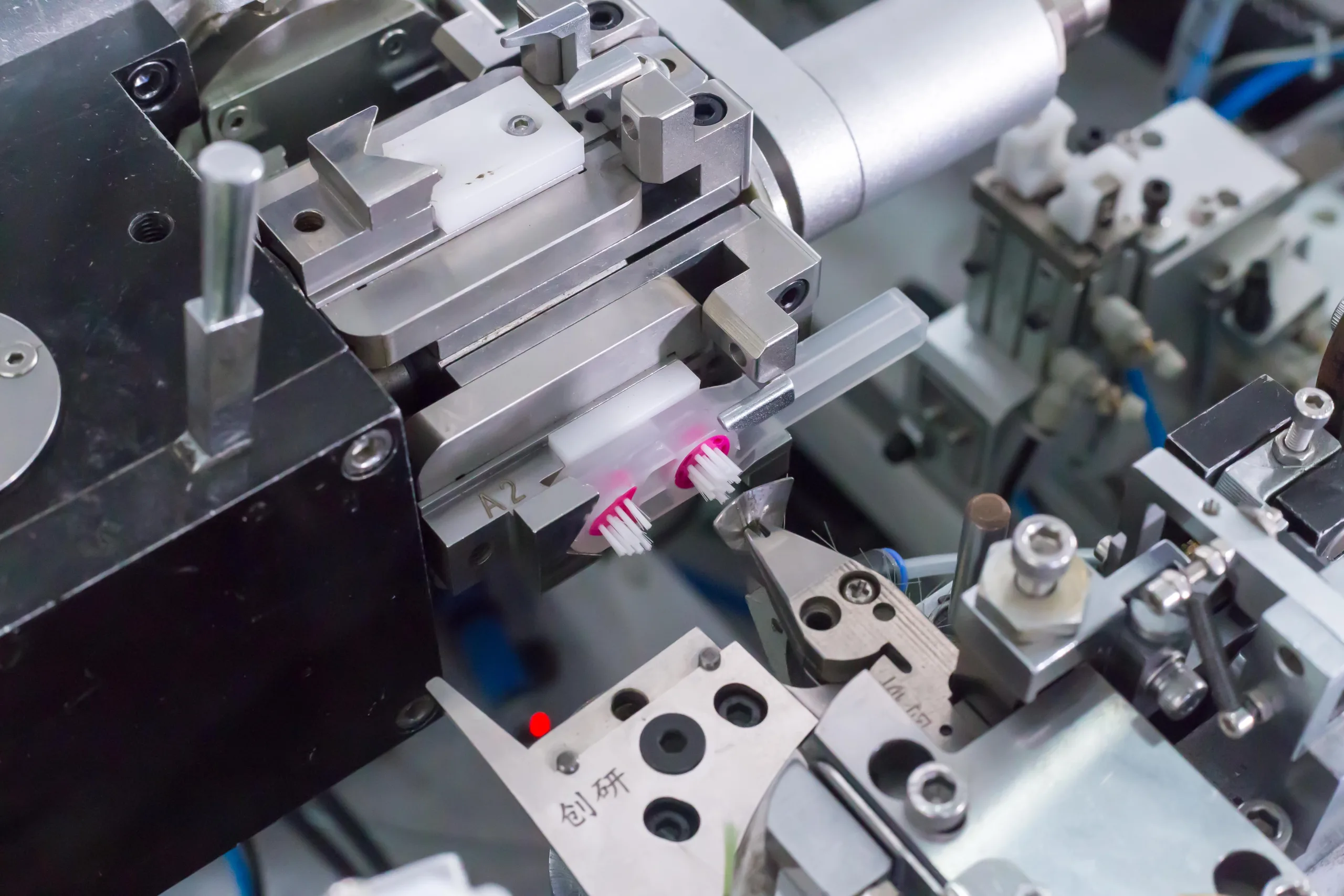

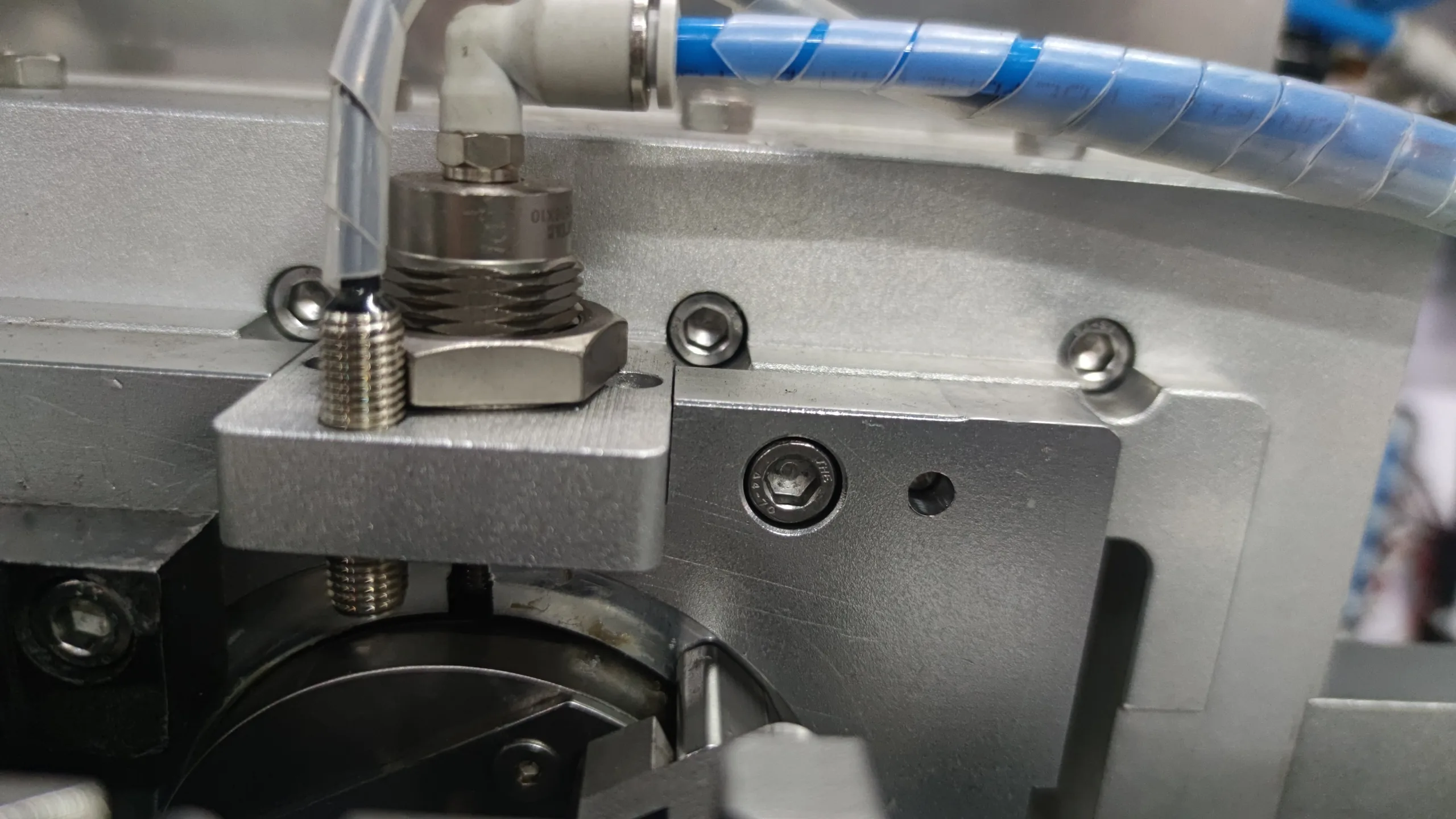

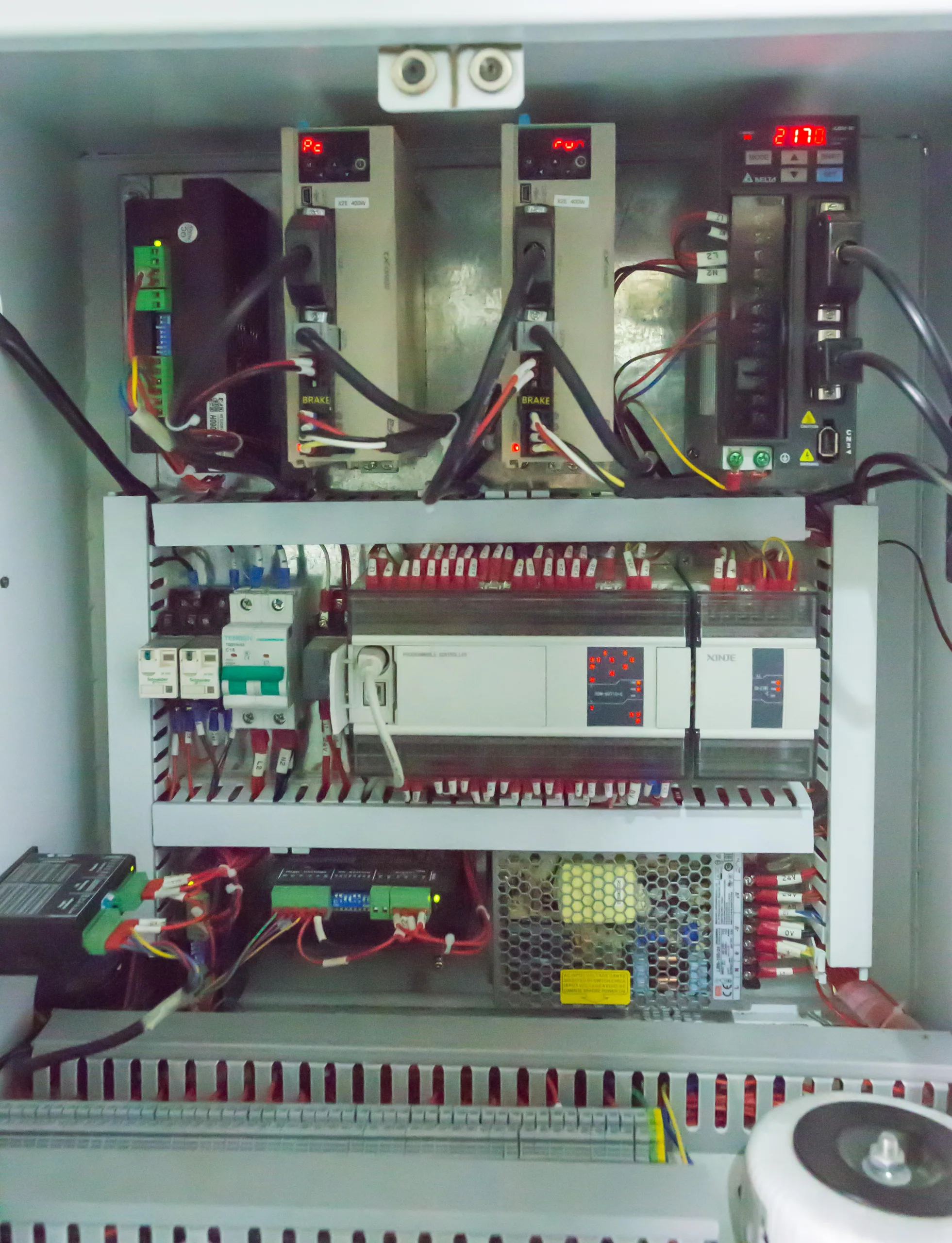

- Toothbrush Tufting Machine

- Toothbrush Trimming Machine

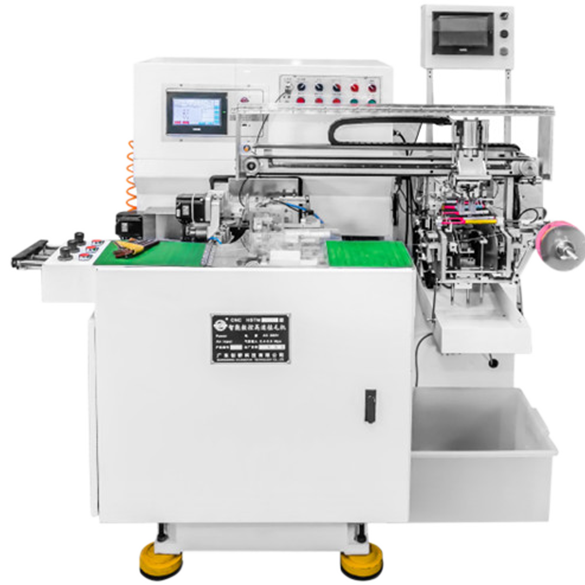

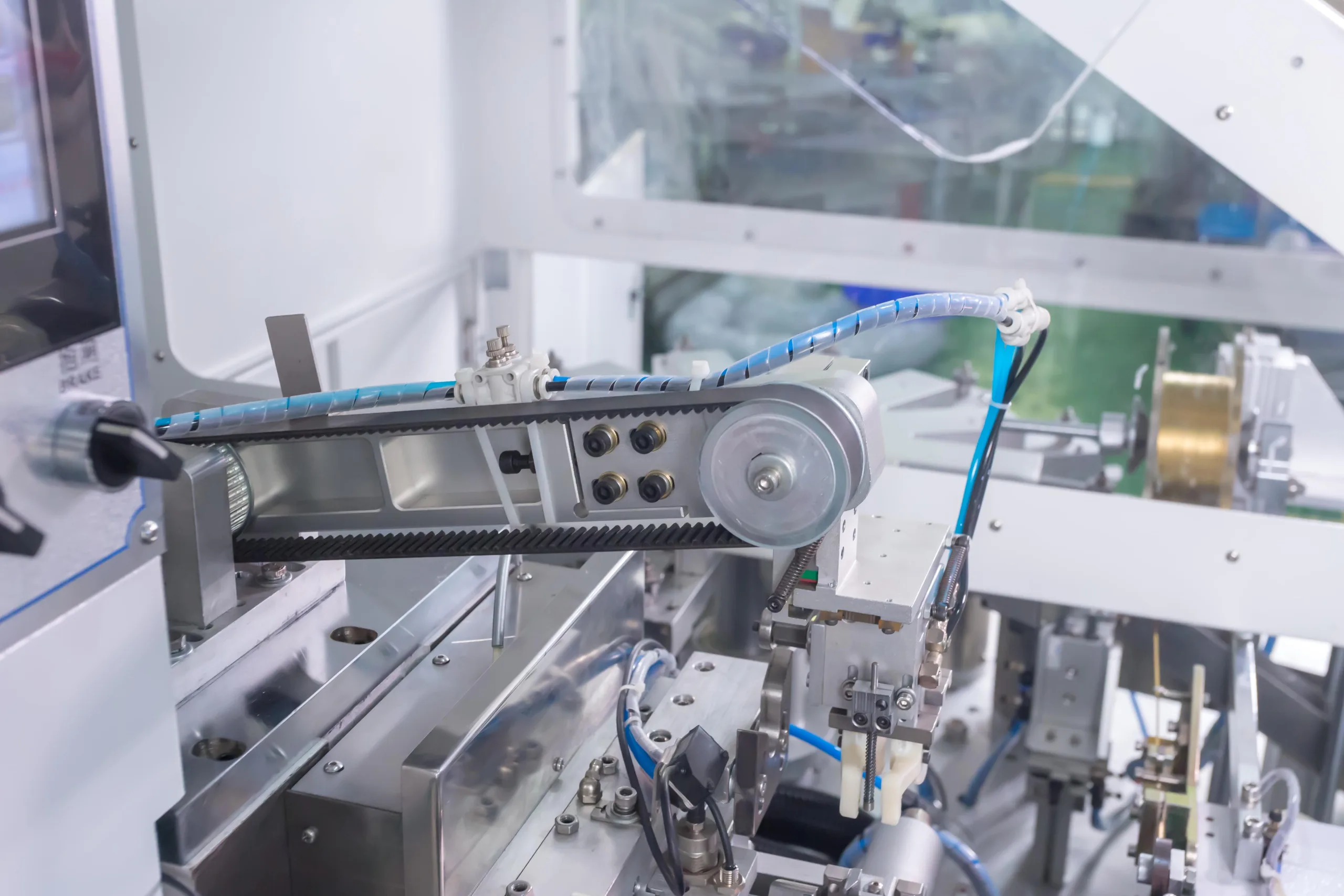

- Toothbrush Tufting & Trimming Integrated Machine

- Toothbrush Packing Machine

- Toothbrush Hot Foil Stamping Machine

- Toothbrush Filament Cutting Machine

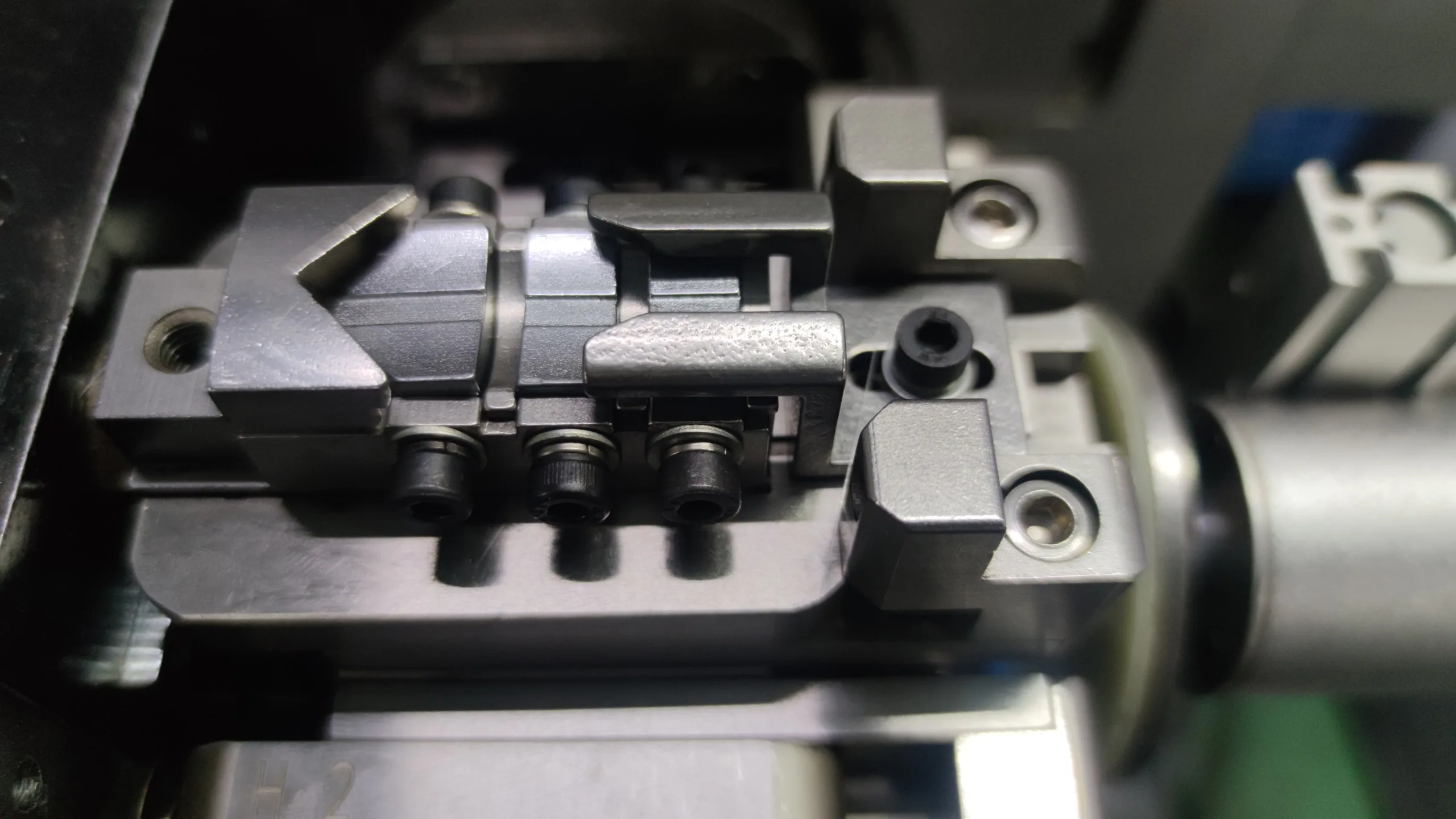

- Toothbrush Machine Robot Manipulator

- Toothbrush Plastic Injection Machine

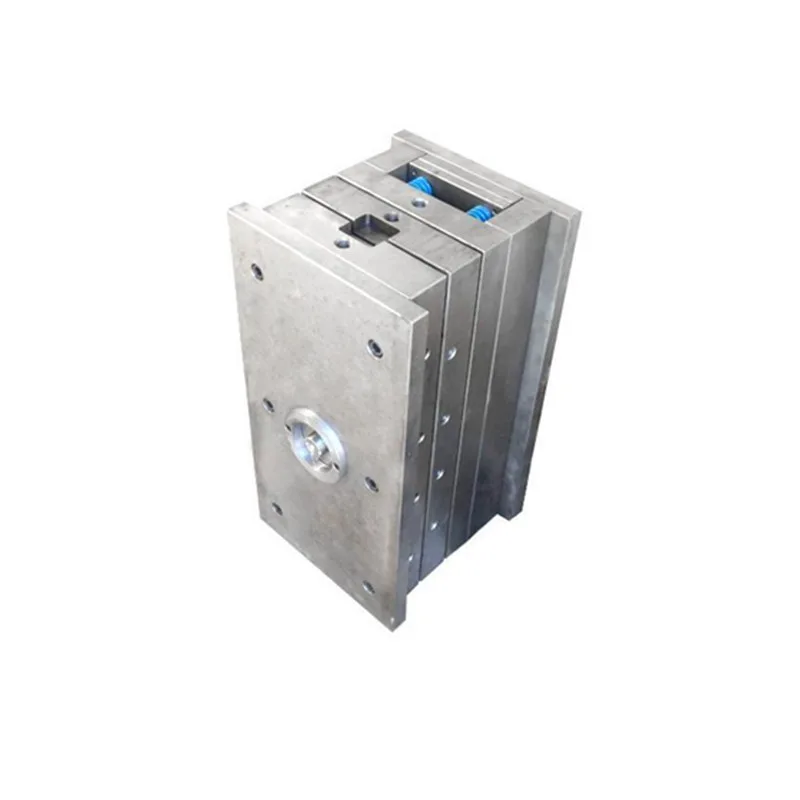

- Toothbrush Plastic Injection Mold

- Eyebrow brush machine