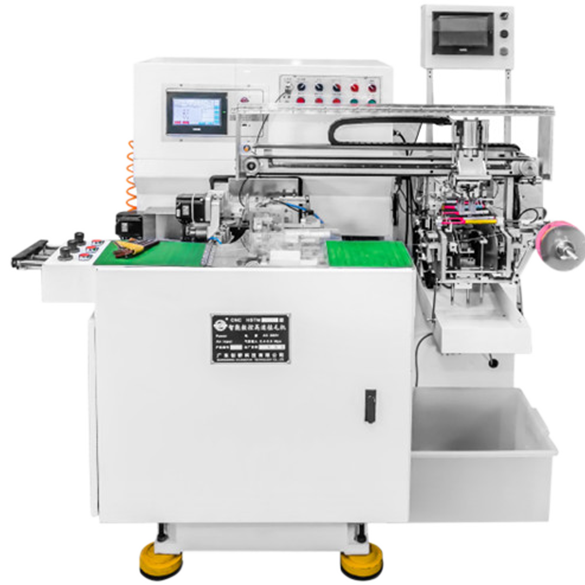

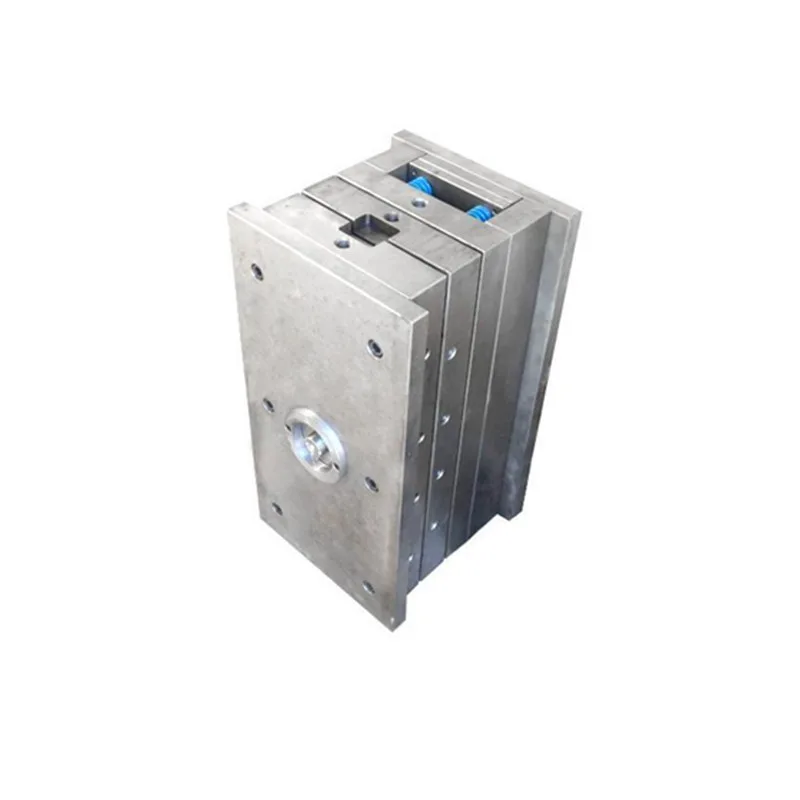

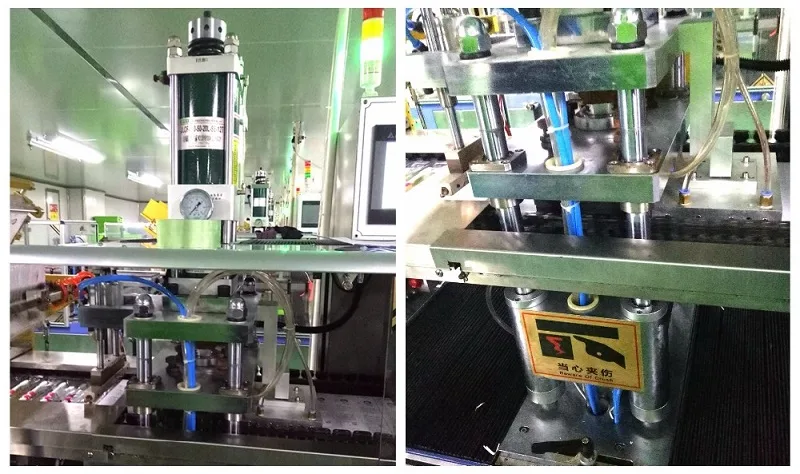

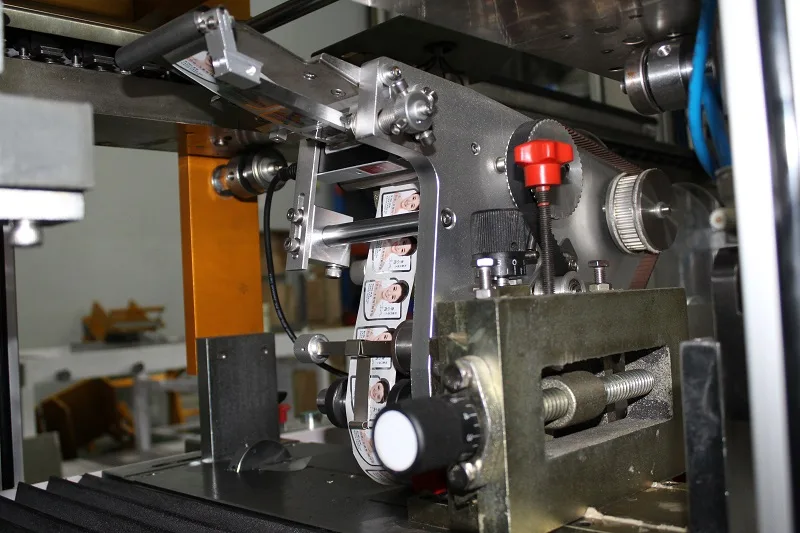

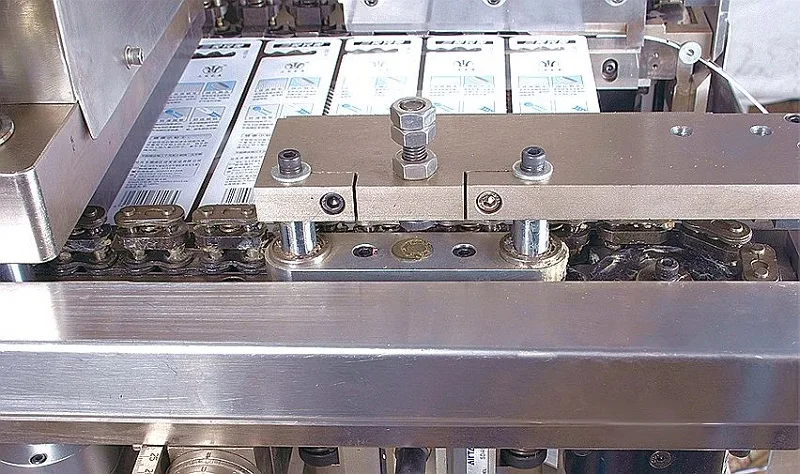

Based on former toothbrush packing technology from Korea Xinya and German our researchers took the initiative to develop a new type of Automatic Toothbrush Blister Labeling & Packing Machine,combining with the new toothbrush in the market.Comprised of automatic paper setting,thermal synthesis technology and punching shear,this machine applies full Servo labeling,enjoying high-tech imported CNC coding and PLC programmable logic ,which gives this new machines an edge in high efficiency,high stability high adjustability,low cost of molding,convenient replacment,low wear,low noise level and so on.

This machine has been obtained a number of nationak technical invention patents.

The packing machine won the “China’s scientific and technological innovation and invention achievements”