1. The main oscillation circuit adopts distributed parametric cavity and well-designed high-frequency transmission tuning system to make its oscillation stable, high efficiency, uniform heating, strong load capacity, complete and reliable control protection.

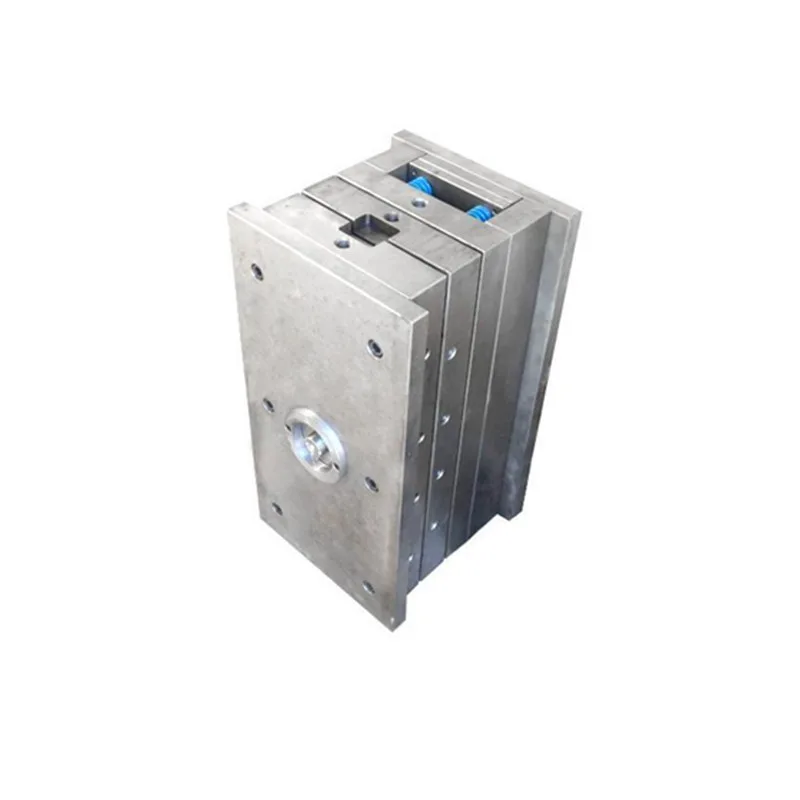

2. The resonant cavity is unique in design, with high quality factor, reasonable structure, high electromagnetic conversion rate, good frequency stability, and meets the international CISFR standard requirements, which is easy to match with the load.

3. The main high-frequency tube adopts high-frequency medium heating equipment oscillator special tube 8T85RB. The tube has the advantages of small volume, high power, long life, and low energy consumption.

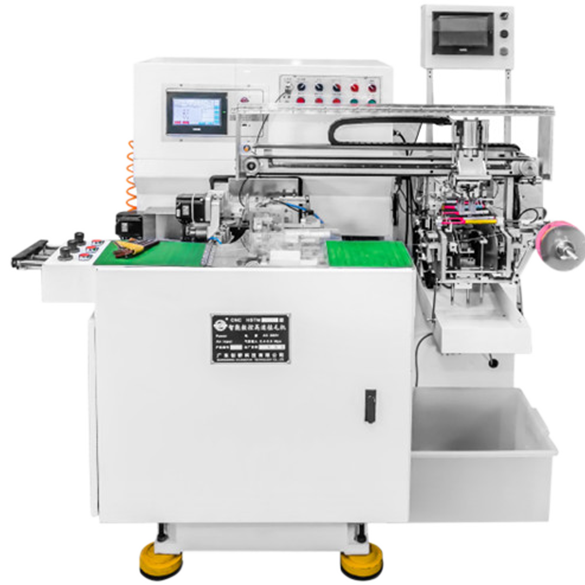

4. The mechanical transmission design is reasonable and perfect, the head is stable up and down, the pressure is adjustable, and the trolley is stable and accurate.

5. It has complete functions, simple and convenient operation, and is widely used. It is an ideal medium heating device.

Note: The service life of the high-voltage AC contactor is 500,000 times. When the service life exceeds the service life, the contact is easy to stick to damage the equipment. Therefore, the device adds a protective measure: when the contact is stuck, the voltage of the tube filament is cut off and the voltmeter The indication is zero. (The touch screen is still displayed)